Barras 3D

For those that have been paying attention to the mobile workshop build you will of seen alot of 3D printing has been involved.

It has been used for many different solutions in the barras blades world

I first discovered 3D printing about 3 years ago. I had a desire to improve my CAD (Computer Aided Design) skills so that I could get things built using CNC plasma cutting etc. However because I found it easier to use another kind of CAD (Cardboard Aided Design) I never got round to it. And because I never got round to improving my skills on a computer i never got much made using CNC services.

To break this cycle I considered a 3D printer which could turn a electronic 3D model into a physical 3D model. The problem was looking at the online 3D printing community most of it was producing 3D printed landfill fodder. This somewhat put me off until I saw a few people actually making something useful using a 3D printer.

This pushed me towards purchasing a Prusa Mk3 as it was getting good reviews as a reliable machine. There are far cheaper machines on the market which can do the same but their online communities seemed to be very much geared towards getting the machines to actually work.

I bought this as a kit which taught me alot about how to design for 3D printing as well how robust a 3D print can be.

First functional print

A dog lead hanger which is still in use today

Fast forward to mid 2021 and I have been slowly improving my skills with CAD and have been using it to solve various problems I have encountered in the growth of barras blades. With dust extractors, brackets, control panels, cable clips and all manners of stuff in the mobile workshop. Nothing that would really be needed or wanted by anyone else as most of it was designed for me and my needs but still the printer made it into tech corner

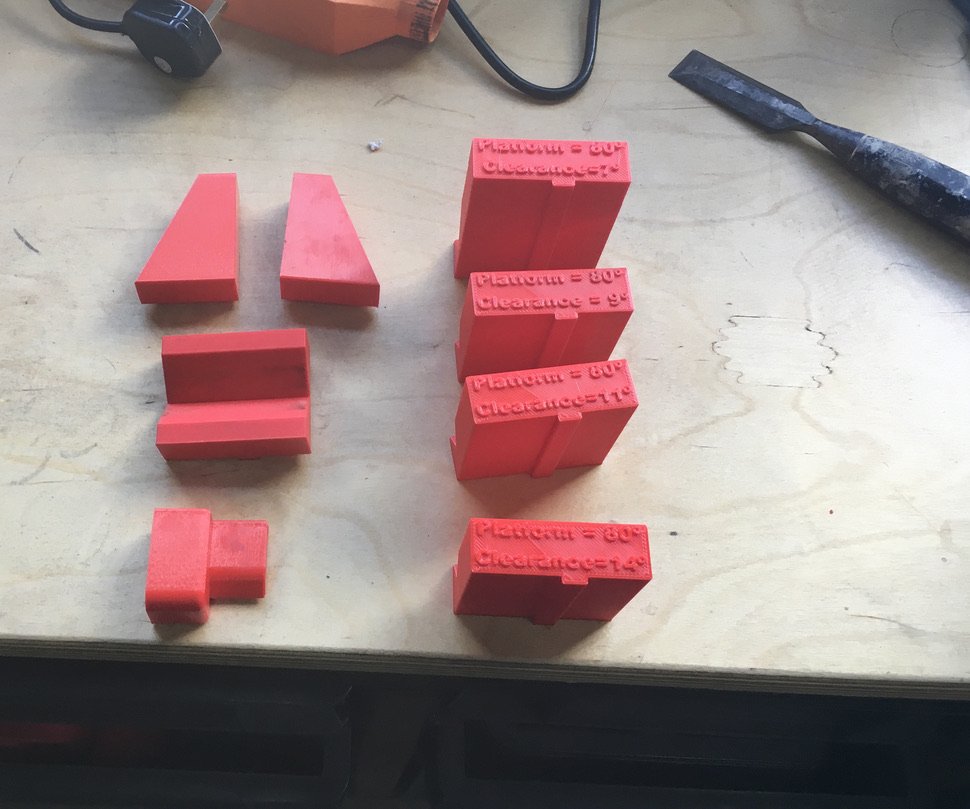

Then I designed a set of guides for the Sorby for sharpening drills. I posted about this in the secret underground sharpeners group and a few folk wanted a set so i printed them out and sent them off. Charging enough to cover my costs. These were spotted by Robin who runs the most famous sharpening school in the UK and the only one approved by Wolff industries in the UK. He saw the potential in them and asked me to make him a set which he could try out in the training school.

First set of guides for a customer

He was very impressed with them and asked me to make a pile of them which I did and they are now for sale in the supply side of the training school.

They are slowly selling and the feedback on them is very good.

Around this time Prusa released their much awaited XL model which I have made a pre-order on.

I think it is time for me to make the printers earn their keep so I am starting up Barras 3D was going to be called barras printing but Helen suggested barras 3D which I prefer

Barras 3D will be offering

3D printing services for those that have already got their own 3D designs

Simple CAD services for those needing a quick 3D or 2D model

Advice on using 3D printing for problem solving in your home or business

This company will run in parallel to barras blades and barras cages

Still early days but watch the blog and the website for updates and progress

The first step is a facebook page

Then i think i shall have to get looby to make me a logo