What scissors to buy?

A short and concise long meandering bit on scissors for groomers or hairdressers, but it will be ignored and you’ll buy the shiny expensive ones with sparkly bits or the ones with pawprints if you are a groomer…… You know i’m right

I’d encourage you to read this from beginning to end but for those with a short attention span i’ll put links in here.

So what does a grumpy old engineer know about scissors?

I know alot about tools as I have been using them since I could hold a hammer and a pair of scissors is a tool. They let you do a job. They are no different from a spanner, a pair of pliers or a socket set in many ways.

A spanner, a pair of pliers or a socket set can all be used to undo a nut.

However an ultra expensive pair of snap on pliers will be significantly worse at undoing a nut than the right sized spanner from the middle row of Aldi.

Its not the cost it is fitness for purpose, scissors are exactly the same. A pair of £500 hair dressing scissors really aren’t the right tool for trimming around the feet of a wriggling dog.

For scissors used for hair cutting they can be divided into 3 basic types………………….

Before we get there lets talk about cutting stuff. There is two basic ways of cutting stuff. There is shearing and slicing

To shear stuff you impart a shear stress in the material and it fails allowing it to be divided. For this you want a very low angle of the blade for strength. A steel shear which is like a giant pair of scissors can cut through sheet steel and they have an angle of basically 80º. A large shear can cut through a piece of 5mm thick steel but it will be driven by either a 3 foot long handle for small ones of a big hydraulic ram for the big ones. Some are rated at over 100tons for the really big ones.

However if you expect these to cut a piece of paper, not a chance. This is due to tedious things like blade angle, clearances etc.

So shearing is very high effort but very robust blades.

Now consider the tomato. You’ve all tried cutting one with a blunt knife and it’s more sort of a squashing process than a fine slicing process. Now imagine what would happen if you tried cutting a tomato with a blade out of a steel shear. We are in soup territory instead of fine slices.

So a shearing action won’t work here.

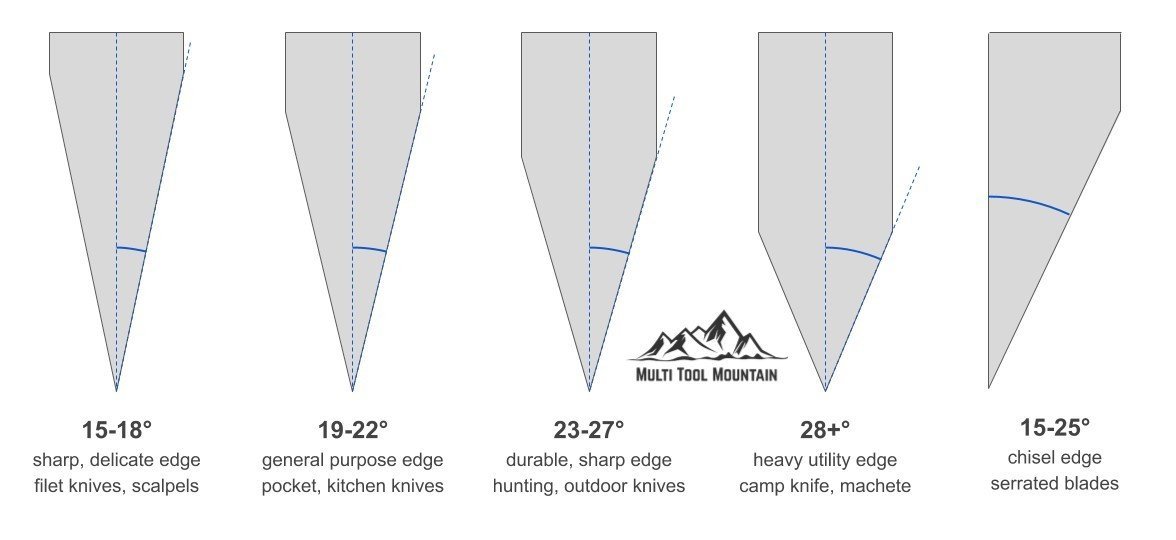

Instead you want a thin sharp edge that will divide the tomato. Which is why chef knifes have slightly different angles for different tasks. A very fine angle for soft things like tomatoes. If you only chopped tomatoes then you could get away with an angle like 10º. However the downside to a very fine angle is there is very little metal supporting the cutting edge so it will easily distort and be damaged.

So you won’t find a knife with an angle as fine as 10º the finest in a kitchen is about 16º. For heavier tasks which will put more stress on the cutting edge then you are wanting more material behind the cutting edge so cleavers etc will be 30º or more.

Slicing is much easier so needs little effort but the blades are very delicate.

Now shearing and slicing are actually two ends of the one scale. At the shearing end (80º) you have high effort robust blades. At the slicing end (30º) of the scale it is low effort but delicate blades. Shearing is for stuff like steel sheet, slicing is for stuff like ripe tomatoes. Neither of which is something you will of probably been cutting in your house recently with a pair of scissors. You will of been cutting things like cardboard or fabric. Which aren’t as hard as steel but are harder than ripe tomatoes.

Whats half way between 80º and 30º?

Its 55º and if you go grab a general use pair of scissors they won’t be far from this angle.

So far I have been using the same way to measure knife angles and scissor angles. If only it was that easy.

On the left hand side of the picture and this is a typical average knife where it is 15º a side which gives an angle of 30º

Nice and simple

On the right hand side is a scissor blade and using exactly the same measurement it’s 80º

WRONG Scissors are measured on the clearance angle so the scissor blade is 10º

Why do we do this?

I haven’t a clue and frankly I wish they would stop it. I blame America as if there is a stupid way of measuring things it is probably them….

ANYWAY

What you need to know for Scissors is 0º to 10º is something heavy duty, 20 to 30º more general use and over 30º is something finer and more delicate.

That is blade angle covered but there is slightly more to it with different ways of making a pair of scissor blades.

There is Bevel edge, Convex and Semi-convex

Bevel Edge scissors

This is normally the cheap end of the hair cutting scissors, but some of them such as Roselines make perfectly acceptable grooming scissors. With care they can also be good value for money

But they are not always cheap scissors. Some very nice Jowells scissors are bevel edge. I would far rather have a high end well made pair of bevel edge scissors than a pair of badly made cheap convex edge scissors

For hair cutting these tend to be in the range from 25º to 35º cutting angle

Advantages

Cheaper to make

So you should get a better quality scissor at the same cost point

Easier to sharpen with the TAS being designed for them

Easier to sharpen = happy sharpener

More robust

Less likely to be badly damaged WHEN you drop them

Can take serrations easily from the Corru-gator

We will cover serrations later in this section

Disadvantages

Not as razor sharp as some other styles so may not be as suited to some hair cutting techniques

This is mainly due to limitations in geometry when going to finer angles

Tends to dominate the cheaper end of the market

Not really a disadvantage more sort of a fact

Typical bevel edge blade profile

Convex Edge Scissors

Otherwise known as the Japanese style of scissors. This used to be exclusively high end scissors with the expected decent workmanship and materials. These days, not so much. You can get fully convex scissors made from abject garbage. Instead of a straight edge like a bevel edge scissor they have a more curved profile which gives a wee bit more support to the blade edge. This gives a wee bit more strength at finer cutting angles. They will also have the back of the scissors scalloped out with an hollow which makes them lighter and will also reducing friction as you aren’t sliding two big flat pieces of metal against each other.

these tend to be in the 30º to 40º cutting angle.

Advantages

A very slightly rusty Convex blade. Macro lenses do find the slightest details

More likely to be a high end scissors

This can be seen with better build quality as well as higher quality steels

Sharper than a bevel edge

This can mean they are more suited to advanced hair dressing techniques

Smaller sliding surfaces

This can make them easier to use

Owww they look lovely

Disadvantages

More difficult to sharpen

Not an issue if you have a flat hone

If you have bought those pretty purple ones with the coating over the entire blade they won’t be pretty and purple by the time I’ve sharpened them properly

More delicate

If you drop them or aren’t careful with them then they are taking a chip out of the edge and they are catching like a bugger

More expensive to make

For the same cost as a bevel edge you are getting poorer material etc

A typical convex edge scissor

Semi convex Scissor

Normally this is listed as the 2nd type of scissor in any list of scissor types but as I always forge my own path I’ll put them last. They share many qualities with both the bevel edge and the convex. They tend to be a better quality scissor than a bevel edge BUT as I said before a good quality bevel edge is superior to a poor semi or fully convex scissor. They normally have a hollow grind on the back which results in lower cutting forces on the handles.

Advantages

The end of this blade is about 4mm tall. I need to get a better lighting setup for macro photography

Sharper than a pure bevel edge scissor

But not as sharp as a convex

Stronger blade than a convex scissor

But more delicate than a bevel edge

Can put pretty colours and finishes on the convex part of the blade and it should survive sharpening

Reasonably easy to sharpen

Can be serrated

Disadvantages

Almost as difficult to make as a full convex

Semi convex blade profile

Looking at the above picture you will see how I have got the blade profile is I have simply removed the section between profile 1 and 2 (it’s called a loft cut in CAD) and this has a straight bevel edge after the delicate curved section has been removed.

I’ve done this in a CAD program. Why can’t it be done in the real world?

There is no reason why it can’t be done. A common bodge for those without a flat hone to sharpen your scissors is to take the convex edge off using the TAS grinder and to replace it with a very small bevel. So as i say on the TAS page if you are a hairdresser with high end scissors and someone turns up with just a TAS be cautious.

The hollow grind

Both the convex and semi convex scissors will have a hollow grind on the back. Which is a hollow formed by grinding.

This reduces friction when the scissors are closing. This reduces cutting forces on the handles as well as helping the edge to last longer as it isn’t rubbing on the back of other blade so much.

This is why on some scissors you will see a shiny line on the inside of the scissors like this below.

Micro Serrations

You either love them or you hate them in your scissors however a many people have them in their grooming scissors and have no idea they are there.

This is where scissors designed for dog groomers are normally differentiated from cheap hair dressing scissors which someone has painted a pawprint on. A good way to tell if you have a serrated edge apart from looking at it is to take your thumb nail and run it down the edge. If you feel a vibration then they are probably serrated. The same comes from opening and closing the scissors you may feel a slight vibration

There is two main advantages in having them.

Firstly they will grip hair instead of letting it slide out of the blades so you get a more controllable cut. As each tooth encounters some hairs it will be gripped and then it will be cut.

Secondly they are a tougher edge than a plain straight edge. Not only do they appear to be more damage resistant than a plain edge but also if you do pick up a tiny nick in your blade then you won’t notice it as much.

The downside to a sharpener of having serrations is either you have to do alot of sodding around with a special file to cut them or you use a machine which only does serrations. I have a machine for applying serrations. So apart from having to drag it out of the drawer it’s no major hassle.

The machine I have has a fine wheel fitted which is 72tpi. This is teeth per inch and 72 teeth in one inch results in teeth which are roughly 0.3mm apart.

The downside of this machine is it is expensive to run as they use very expensive diamond wheels which don’t last forever also it takes alot out of the scissor blade. Because of this is you hand me a scissor which is serrated is I’ll sharpen the plain blade and then test the scissors. Most of the time they perform fine due to the serrated blade. If they don’t then i’ll drag the machine out of the bottom drawer and put the serrations on.

If your scissors haven’t got serrations most of the time they can be added. Just ask your sharpener.

Materials

A part of my background is an a valve engineer in oil and gas. Part of this means I have a basic understanding of metal alloys. With a basic understanding of metals I know my knowledge even barely scratches the surface when compared to a proper metallurgist. That said I know alot more then most people.

A lot of makers boast how their scissors are made from stainless steel or japanese stainless steel.

What does this mean and is it good?

In short it means absolutely nothing. Stainless steel is a family of steel alloys ranging from soft as pooh to hard as glass. Some are magnetic, some aren’t. Properties change depending on heat treatment, forming processes, alloy elements etc. Each blend of stainless steel is given a number which relates to what the ingrediants are. Its like making a cake but hotter as each recipe gives a slightly different results. By changing the amount of carbon and other elements you can change the properties of a steel. These properties can be cost, strength, hardness, springiness etc. You also discover as you increase one property it can reduce others. You can’t have a really springy and hard material. Everything is a compromise. Also there is no blend of stainless steel which is made exclusively in japan. There is japanese foundries which have better control over the process then some no name chinese foundries.

However the recipe is just one part of the story.

You could take one blend of stainless steel and cast it into a scissor which would have completely different properties to the same material being hot forged into the same shape. Alot of how a metal performs is down to how the internal crystal structure is controlled and this greatly relates to temperature and time. It is a massive rabbit hole it get into and I find it utterly facsinating.

So without the proper material certificates and heat treatment records along with a full traceability record with heat numbers etc you haven’t got a clue what is going on with the materials in a pair of scissors.

Sadly this is a matter entirely of trust when it comes to buying a pair of scissors. As there is no cheap and easy way to check what a pair of scissors are made of.

You could hardness test and PMI a pair of scissors which would give you a reasonable idea of what is but this would be a bit more costly than the scissors themselves.

All you can really do is to buy from trusted brands and sources NOT EBAY.

As trusted brands will use decent alloys from trusted foundries

Rust

There is a common idea that a good stainless steel won’t rust.

The first question is what is a good stainless steel? And why is it good?

As I mentioned above all steel blends are a compromise and as you increase the elements which make a stainless steel resistant to corrosion you reduce other desirable properties. You could make a pair of scissors from a material that was utterly resistant to any form of corrosion but they would be pretty awful scissors.

At the other end of the scale my wife has a very nice japanese knife which sharpens to a razor very easily and it stays like a razor. However you can damn near watch it rust as it is a high carbon steel with nothing in it that would make it a stainless steel. This material would probably make an wonderful pair of scissors but no one would buy them as they would look like pooh a few days after being in the salon.

So why do I mention this?

If you have invested in a decent pair of scissors then they will NOT be made of stainless steel which has very good corrosion resistance.

If you don’t look after them then they will start to corrode.

Dry them after cleaning them and keep ontop of oiling them. Don’t leave them overnight in any cleaning solution and then chuck them dirty into a drawer.

Conclusion

So what does all of this mean to a groomer or a hair dresser?

In some ways sod all as many online sellers don’t list what type of blades scissors are. However I really don’t recommend buying scissors online as it is a massively subjective thing. You might love one pair of scissors but hate a pair costing twice the amount. You don’t know this until you have them in your hand. I have yet to meet a groomer who hasn’t said “i bought these online, they are 5hite”

Up here in the wild north of scotland it is difficult to get hands on with scissors. I carry a small range of scissors from Kanpeki as I have faith in their product but you might hate them. However I’d far rather you picked up a demo pair and hated them rather than buy them and then hate them.

Now assuming you are stood in a scissor shop and they have all of their scissors out and ready to try and they are properly labeled and they are all the same cost.

What should you go for?

I sell a range of Kanpeki scissors for groomers which have features I like but i’m not going to say they are the only choice

If you are a Groomer then your clients tend to a wee bit more likely to of rolled in a muddy puddle before coming into you. They will also tend not to stay still very much and have a habit of kicking your scissors onto the floor. To this end I’d recommend a more robust scissor either a bevel or semi convex type. Probably with a serration.

If you are an experienced hairdresser then your clients won’t of rolled in a muddy puddle, will stay still and are unlikely to be stood on a table kicking your scissors to the floor (unless Gin is involved) To this end I’d be pointing you towards a nice pair of convex scissors. For a trainee hairdresser i’d be pointing you at a decent pair of bevel or semi convex scissors as they will be more tolerant of whoopsies

If you are a barber then the jury is still out on the whole muddy puddles, staying still and stood on the table elements.

but it is a very subjective thing which is hugely down to personal preference.

So you have reached the end of this page and know far more about scissors, how they work, what types they are but I still haven’t told you what to buy other than to buy known brands and to avoid the online bargains.

Sorry about that, hope you learnt something