Most of the machinery I have purchased for this business has come from the USA as Wolff who build the TAS and the Nebraska clipper hone are world leaders in this field

The TAS ookami gold system used to be the goto machine for high end scissors. But over the past 5 to 10 years the Japanese style of scissors which are fully convex have become more and more popular.

These can be sharpened in two ways on the TAS system. One is a workaround the other is a total bodge.

Hairdressers if you see someone sharpening your expensive Japanese style scissors on this machine be wary

The best way to sharpen fully convex Japanese style scissors is using a flat hone with a arm to control the maximum angle you can put the scissor blade to.

Of course Wolff industries have produced a very good machine to let sharpeners sharpen these scissors. It very light and compact. It easy put in a small toolbox and carried into a salon to let sharpeners work in a tiny space. One sharpener in London carries his entire kit on a moped.

This is the machine I trained on.

But it is a very expensive machine and to purchase it I would be borrowing even more money.

Had I not popped down to spend a day with Ryan Hill at Northumbrian Sharpening then I’d probably be borrowing the extra cash.

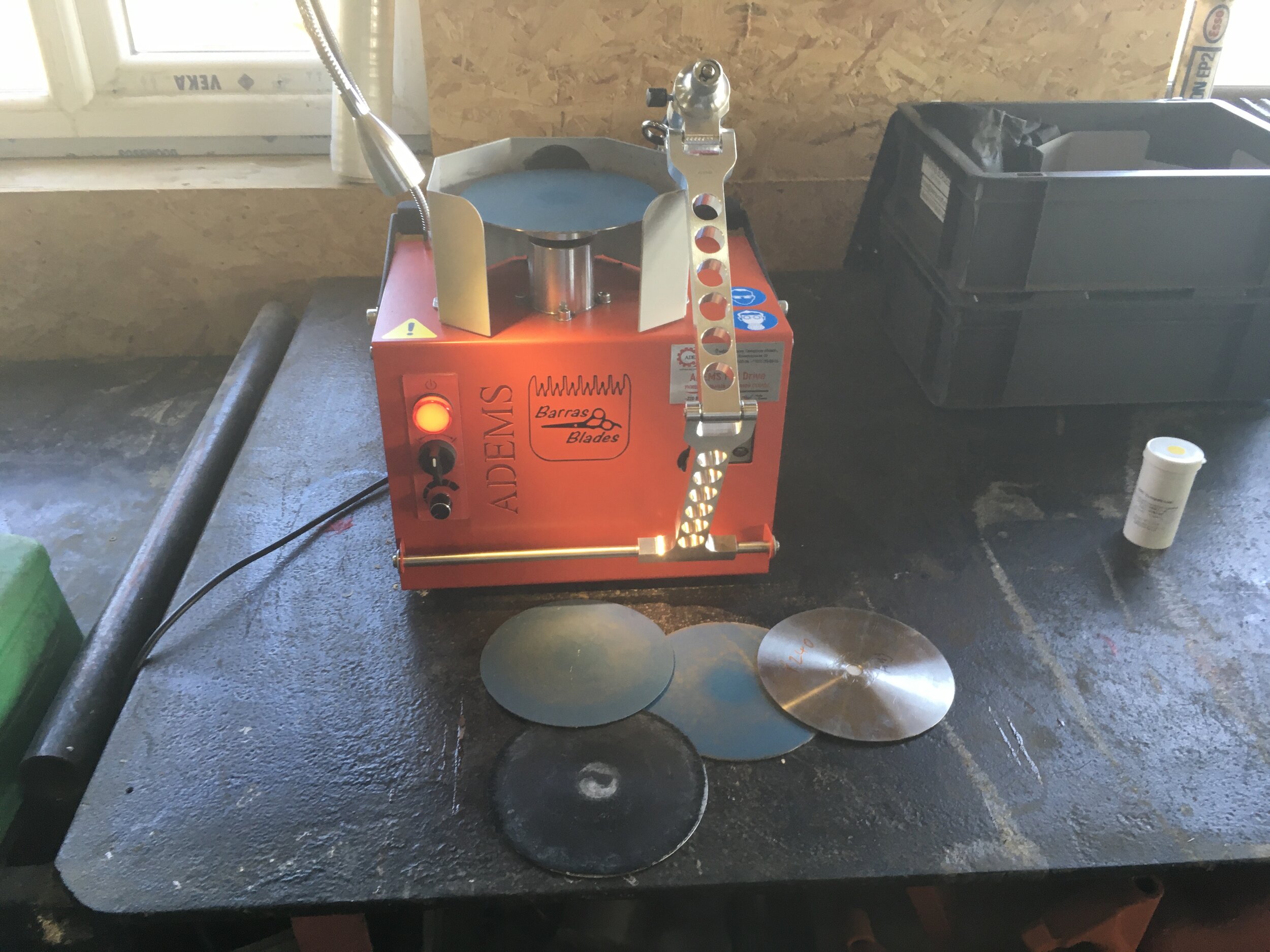

He had discovered the Russian version of a flat hone. The Adems Full drive.

I had a short play with it and saw it in action and I was impressed

It’s built like you’d expect Russians to build something. It’s easily twice the size and weight of a hira-to. It’s built like a tank.

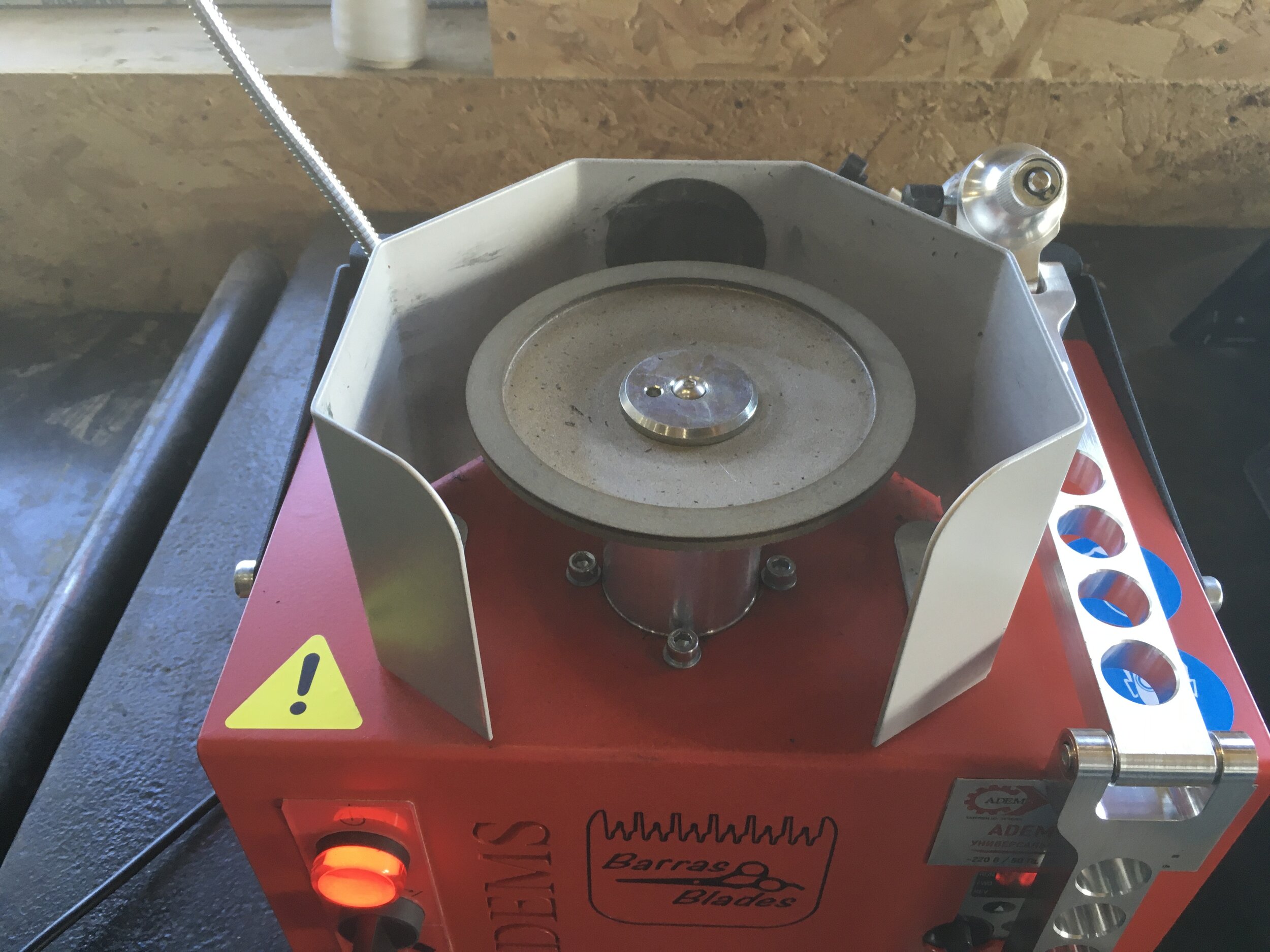

It operates in a very similar way with a free floating arm which restricts the angle at which you can hold the blade but it allows you full and free movement on placing it on the spinning plate. The spinning plate has swappable metal discs which are fitted with various grades of abrasives as well as a polishing pad which allow you to grind and then polish a scissor until it is a mirror finish and razor sharp.

The upside of the Wolff machine is an established support network and a proven import route into the UK.

The Adems machine.

Not so much.

I was confident in the support side of the machine as there is a few videos online that show the internals and after looking at Ryans machine I thought it was made from reasonably standard motors, bearings and electronic drives.

The only big step into the unknown was importing it and communication with Adems. Thankfully Adems office staff speak way better english than my russian. So a few short e-mails later I had a slightly russian looking document to fill in and a bank account to wire the cash to.

After clicking through numerous online warnings from my bank about scams and sending money abroad the cash left my bank account.

Then the waiting began while the machine crawled its was through the glories of russian customs and the fallout from brexit.

3 weeks later two cardboard boxes appear at my door.

Of course I was like a kid at Christmas and forgot completely to actually photograph the contents or the boxes.

The machine with some of the swappable plates

The system for holding a scissor blade. Functionally identical to other flat hones and well made.

BUT the angles are the opposite to the normal way of measuring angles but its easy to compensate for

The magnetic chuck for holding the different plates

I didn’t just order that basic machine I ordered 3 months of consumables and a few extras.

As where the Adems machine it moves away from the American machine is that the top of the spindle has a reasonably standard profile which means you can pop off the standard size magnet plate and fit.

A larger magnetic plate that lets you sharpen knifes and chisels

Or you can fit it with a diamond cup wheel that lets me sharpen wire cutters and other oddball stuff.

You can even get a small hollow grind plate which allows you todo clipper blades.

Overall I’m very impressed with the machine and think it is very good value.

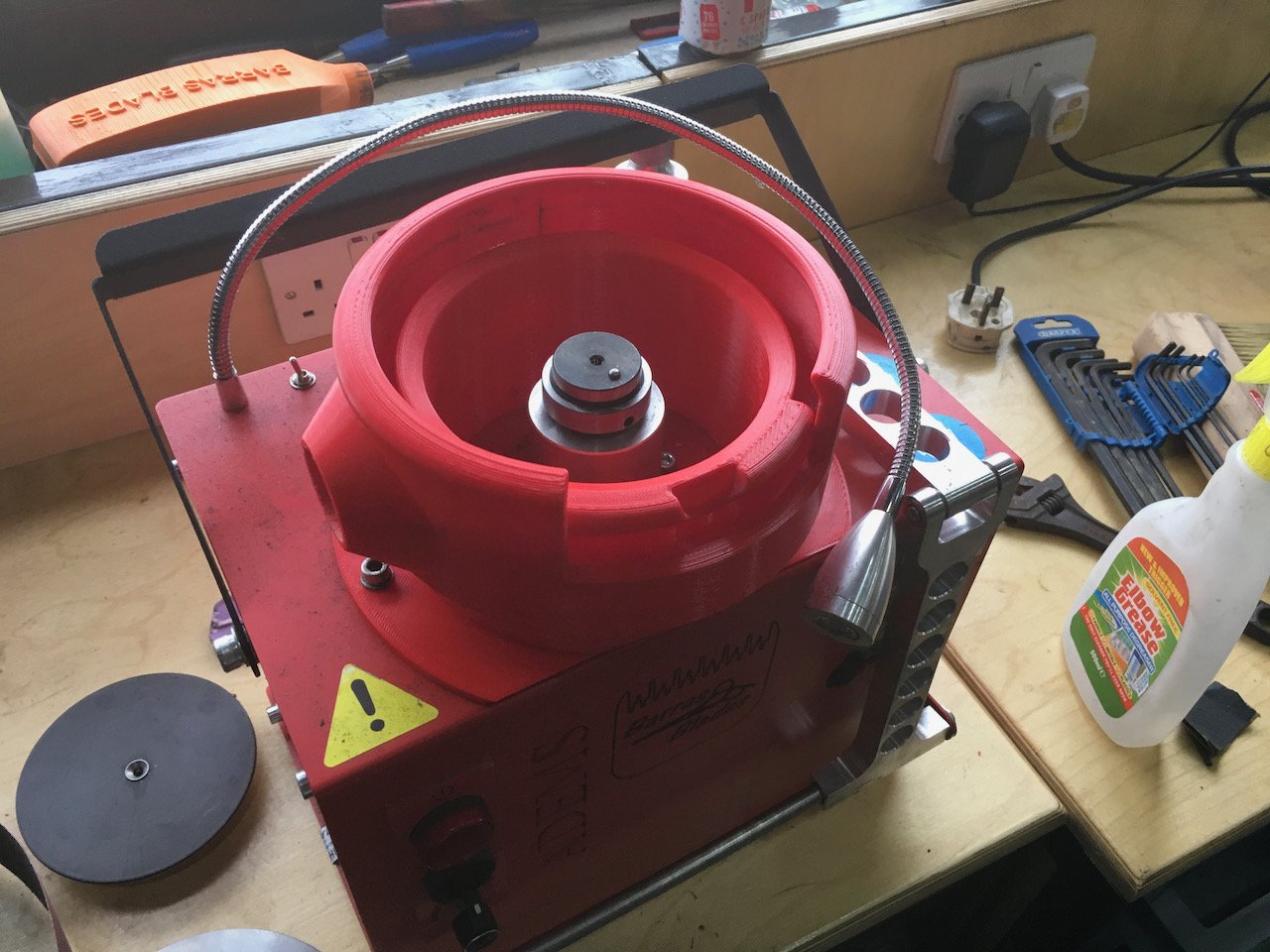

Adems full drive dust extractor

One thing that is a wee bit poor on the Adems is the dust extraction. As standard it comes with a hole in the back of the shield where you could attach a hoover. This is not really very effective. I thought i could do something else.

I am half competent on CAD and I have a 3D printer so after a few iterations I came up with the design seen in the pictures below

The 3MF file can be downloaded here