Lefties

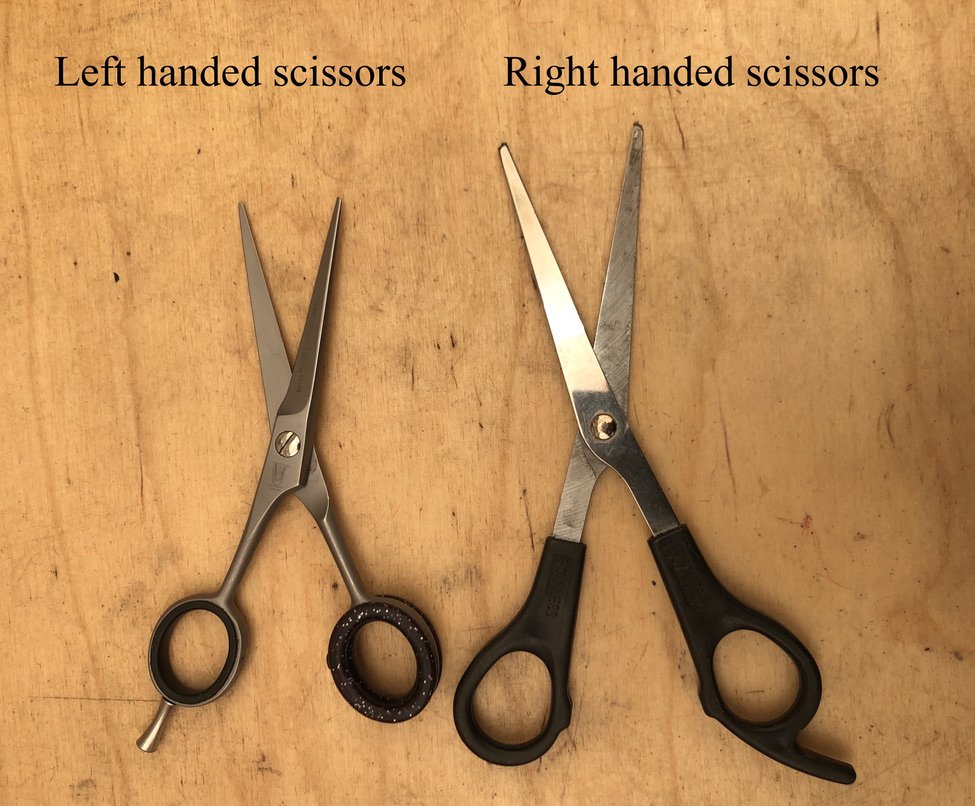

It is said that 10% of people are left handed. Most scissors are designed to be used in a right hand. Using a right handed scissor in your left hand is difficult. So it is not unusual to find high end scissors can be bought in left or right hands. The difference between left and right handed is the way the grind is and how the blades are put together.

You can see how the left and right hand scissors are a mirror image of each other

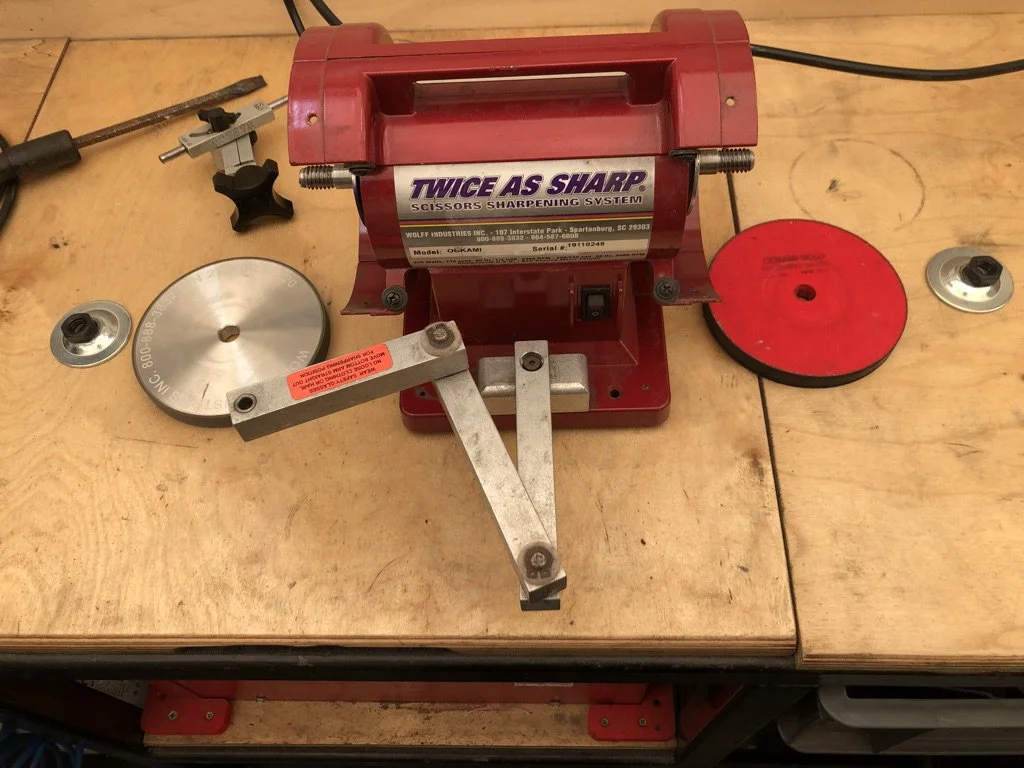

This causes a minor hassle in a few ways as the scissor sharpening machinery are set up for right hand scissors.

TAS normal setup

The normal right hand set up for sharpening scissors with a diamond wheel on the left hand side and the polishing wheel on the right hand side

Sharpening clamp

The clamp for sharpening has two pins marked up for right hand use.

To ensure you get the right angle of grind on the blades you need to swap the wheels over on the TAS which isn’t a an overly difficult task.

You need to take the side covers off, if you still have them fitted. Then undo the nuts which are right and left handed threads.

The wheels are then swapped over and the nuts retightened

Because the diamond wheel (shiny one) has an aluminum centre you don’t have to worry about any balance issues

The grind is done first with the angle being checked and then the diamond wheel used to remove as little material as you can get away with but to still form a burr

Next up is the polishing which uses a fine metal polish on the fibre wheel to give a mirror like finish.

After the grinding and honing is done to one blade the same process is carried out on the other blade. Then some sharpener magic happens with the blades being de-burred, reassembled and checked etc.

Then come the hard part

Testing which isn’t quite as difficult as you would first think but lets look at the problem first

Right hand scissor

This is how most of you use a pair of scissors. You have your thumb in the thumb ring and you naturally put a sideways pressure on the thumb ring. this causes the blades to pivot on the central fixing and this pushes the blades together which increases the ability of the scissors to cut. You learnt this as a child as your school and/or parents gave you terrible scissors

Left hand scissor

Now lets do the same action with a left hand pair of scissors.

Your muscle memory of pushing the blades together now works against you as you are pushing the blades apart.

This gives worse cutting performance which is not what you want when you are testing a pair of scissors.

From this the first thing that should become screamingly obvious is it is difficult for a right handed person to test a pair of left handed scissors. Bit of a bummer if you are right handed and have a left handed customer.

What isn’t so screamingly obvious is. You can increase the performance of pair of scissors by pushing harder. Fine for me as i’d using the scissor at most 5 times to test it. Also I have quite high hand strength due to what what I do. For a slightly built hair dresser who is using scissor all day putting on alot of side pressure on the blades is going to be tiring and might bring along RSI. Also alot of side pressure will quickly blunt a high end razor sharp scissor.

This is how I test scissors. I put my thumb ontop of the blade and this makes it more difficult to apply side pressure. So when i am testing a left handed scissor I am not pushing the blades apart. This gives me a much better idea of how well the scissors are performing

But crucially this is also done for right handed scissors.

If I use side pressure for testing scissors this will give me an artificially good performance.

This is one method to test hair dressing scissors with some wet single ply tissue paper (bog roll)

The scissors should cut it fine and then when you pull down it should not catch

For the more knowledgeable of you and those who have been reading the machinery pages you will know the TAS is used for bevel and semi bevel type scissors.

It isn’t suitable for high end convex/Japanese style scissors.

For these you need a much more expensive and capable machine called a flat hone

So what complex reconfiguration is needed of this machine?

See below